Ett helt ny sätt at mäter med trådtöjningsgivare

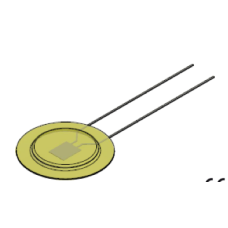

Till skillnad från de konventionella töjningsgivarna (DMS) möjliggör StrainPad töjningsmätningar utan tidsödande montering av töjningsgivare och ger precis samma exakta resultat.

PROBLEM

De för närvarande tillgängliga och standardanvända töjningsgivarna måste anbringas mödosamt genom att fästa dem på den komponent som ska mätas. Om detta inte görs korrekt med högsta precision, resulterar detta vanligtvis i allvarlig förfalskning av de uppmätta värdena. På grund av detta krävs specialutbildad personal för att ansluta ett DMS (töjningsmätare), varför töjningsmätare för närvarande inte används på många områden, förutom i testmiljöer och i laboratoriet.

LÖSNING

I motsats till de redan tillgängliga töjningsgivarna som nämns ovan, är våra StrainPads fästa på komponenten som ska mätas med en enkel kraftmonterad anslutning. Eventuell inblandad personal behöver inte uppmärksamma stor noggrannhet. Detta möjliggör enkel och mångsidig användning av StrainPads och möjliggör töjningsmätning utan att fastna. StrainPad är det perfekta alternativet till töjningsmätaren (DMS). En så kallad monteringsanordning krävs för att använda StrainPad. Dessa monteringsanordningar trycker StrainPad så kraftigt mot komponenten som jag uppmätt att friktionsingrepp uppstår. Monteringen av StrainPad med motsvarande monteringsanordning är oförstörande, mycket enkel och utförs på några sekunder. Vi erbjuder olika standardmonteringsanordningar, såsom magnethållare för plana ytor, eller våra ringmätare för mätcylindrar. Dessutom finns det även möjlighet att designa kundspecifika monteringsenheter för just din applikation. Ta bara kontakt med oss!

Letar du efter en snabb och enkel lösning för töjningsmätningar utan krångel med limning? Tveka då inte att kontakta oss med din mätuppgift. Vi kommer att arbeta tillsammans med dig för att hitta en lösning så att du kan hantera dina mätuppgifter effektivt och exakt.

TYPISKA ANVÄNDNINGSOMRÅDEN

Användningsområdena för våra kunder är olika och en lämplig monteringsanordning krävs för appliceringen av vår StrainPad. För standardapplikationer inkluderar vår portfölj till exempel en magnetisk hållare och vår ringmätare. Du är välkommen att kontakta oss angående dina mättekniska utmaningar så hittar vi en skräddarsydd lösning för dig till bästa möjliga pris.

Våra ringmätare används bland annat även för att mäta förlängningen av stagstängerna i formsprutningsmaskiner. I dessa system säkerställer fyra dragstänger att formsprutan stängs korrekt genom att motverka krafterna från plastmassan som sprutas in i formen. Om detta inte sker jämnt kommer formen inte att stänga ordentligt och krafterna kan fördelas över endast tre stag. Detta kan leda till överbelastningar som i sin tur leder till produktionsbortfall eller kvalitetsproblem. Genom att mäta med våra ringmätare kan du avgöra vilken dragstång som inte är korrekt justerad eller är sprucken. Detta möjliggör att lämpliga motåtgärder kan initieras, såsom att justera spolmuttern. Mätningen av dragstångens förlängning utförs vid uppställning av maskinen och ofta efter byte av form eller produkt. Ofta finns dock en ringmätare permanent kvar på en av skenorna för att synliggöra ändringar och vid behov upptäcka och utföra eventuellt nödvändigt underhållsarbete i ett tidigt skede.

FUNKTIONER

- Töjningsmätare alternativ

- Enorma tids- och kostnadsbesparingar

- Ingen utbildad personal behövs

- Ingen limning

- Återanvändbar

- Mångsidig

- Exakta mätresultat

INNOVATIV TRYCKMÄTARE (DMS) APPARAT

Töjningsmätare (DMS) har sedan länge etablerats vid bestämning av mekaniska spänningar och därmed spänningar på material. Deras professionella tillämpning kräver dock mycket tid och utbildad personal, eftersom även de minsta felaktigheter kan leda till fel i mätkedjan. På grund av detta avstår man i praktiken - utanför laboratoriet - ofta från töjningsmätare eftersom ansträngningen och osäkerheterna bedöms som för stora. Med sin patenterade teknologi möjliggör StrainPad töjningsmätning där konventionella töjningsmätare inte kan användas på grund av de nämnda nackdelarna.

TVÅNGSMONTERAD ANSLUTNING

StrainPad fungerar på samma sätt som en konventionell töjningsmätare (DMS). Den största skillnaden mot detta är att StrainPad varken är limmad, skruvad eller svetsad till den komponent som ska mätas. Endast en tvångsmonterad anslutning behöver upprättas mellan den komponent som ska mätas och StrainPad. Vi har många monteringsenheter tillgängliga för dig för denna uppgift. Vi hjälper dig också gärna att möta speciella krav från din sida.

SNABB OCH ENKEL MONTERING

Töjningsmätare måste anbringas mödosamt på den komponent som ska mätas. StrainPad kan vara till hjälp här. StrainPad behöver bara klämmas fast på komponenten som ska mätas. Detta innebär att den kan monteras på några sekunder och omvänt tas bort igen lika snabbt. Som ett resultat erbjuder StrainPad sina kunder avsevärda tidsbesparingar. Dessutom är StrainPad återanvändbar och kan användas igen omedelbart.

ANPASSAD PRODUKTION

Användningsområdena för våra kunder är olika och det är också användningsområdena för vår StrainPad. Detta gör att vi kan erbjuda våra kunder kundspecifika och skräddarsydda produkter. Du förklarar dina utmaningar för oss och vi hittar en skräddarsydd lösning för dig till bästa möjliga pris.

SENSORDATA I REALTID

Vår sensor ger dig också realtidsdata, precis som du är van vid från mätningar med konventionella töjningsmätare (DMS). Observera vårt utbud av mätelektronik och mätförstärkare. Dessa är skräddarsydda efter våra sensorer och gör att du kan mäta töjningar till bästa möjliga pris.

ÅTERANVÄNDBAR

Till skillnad från konventionella töjningsmätare (DMS) är våra StrainPads återanvändbara. Detta ger våra kunder möjlighet att utföra mätningar snabbt och enkelt inom sina respektive applikationer. Genom att spara tidskrävande infästning av konventionella töjningsgivare, reduceras tidsåtgången enormt och kostnaderna per mätuppgift kan också drastiskt minskas. Som ett resultat utökar vår StrainPad applikationsområdet för töjningsgivare enormt. Detta beror på att våra StrainPads är mycket lättare att hantera än konventionella töjningsmätare (DMS). Letar du efter en okomplicerad lösning för din mätuppgift? Kontakta oss så hittar vi en lösning för dig.

IDEALLT INTEGRERAD

Våra StrainPads utökade användningsområdet för töjningsgivare extremt. Detta beror på att våra StrainPads är mycket lättare att hantera än konventionella töjningsmätare (DMS). Letar du efter en okomplicerad lösning för din mätuppgift? Kontakta oss så hittar vi en lösning för dig.

Strainpad - Alternativ för töjningsgivare

- Tillverkare: Octogon Messtechnik

- Artikelnummer: Strainpad

- Tillgänglighet: Pre-Order

Liknande Produkter

Magnethållare- Alternativ för töjningsgivare

Kraft- och töjningsmätningar med bondade töjningsmätare (DMS) har länge använts inom mekanik och anl..

Ringmätare - Alternativ för töjningsgivare

UNIVERSELLT TILLÄMPLIG RINGMÄTARE FÖR MÄTNING PÅ STÄNGAR, AXLAR OCH CYLINDRARDen oktogon ringmätaren..

Lastmätstift - kundanpassade last sensorer- SIL3 | PLE | IP68

Lastmätstift eller bara laststift är kopplingsstift mellan kraftöverförande maskinelement som samtid..

EVL Momentgivare

TEKNISKA FUNKTIONER27 vridmoment varierar från ± 0 - 0,02 Nm upp till 20 000 NmStort inspänningsområ..