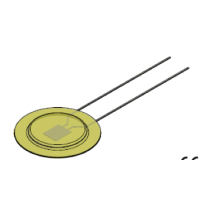

UNIVERSELLT TILLÄMPLIG RINGMÄTARE FÖR MÄTNING PÅ STÄNGAR, AXLAR OCH CYLINDRAR

Den oktogon ringmätaren mäter belastningar på rotationssymmetriska komponenter snabbt och enkelt. På grund av detta är de idealiska för bestämning av förlängningar på stänger i pressar och formsprutningsmaskiner. De drag- och tryckkrafter som uppstår kan bestämmas indirekt via töjningarna. Utöver nya system är ringmätaren även lämplig för eftermontering och är omedelbart klar att användas. Det är det perfekta alternativet till konventionella töjningsmätare.

TYPISKA ANVÄNDNINGSOMRÅDEN

Frekventa användningsområden är mätning av drag- och tryckkrafter i pressar och formsprutningsmaskiner samt mätning av spännkrafter på dessa. Montering av ringmätare rekommenderas för både nya system och som eftermontering. Naturligtvis kan våra ringmätare även användas för vilken annan cylindrisk geometri som helst.

HUR FUNGERAR EN RINGMÄTARE?

Ringmätarna är fastspända på en cylinder eller rundring. StrainPads pressas så hårt på komponenten, som ska mätas, att statisk friktion uppstår mellan de två delarna. På så sätt kan vi uppnå resultat som inte på något sätt är sämre än resultaten med konventionellt bundna töjningsmätare (DMS). Efter installation av våra ringmätare kan töjningar på upp till 1000 μm/m mätas. Våra ringmätare är idealiska för mätning av spänningar på stänger i pressar och formsprutningsmaskiner. De drag- och tryckkrafter som uppstår kan bestämmas indirekt via expansionerna. Utöver nya system är ringmätarna även lämpliga för eftermontering och är redo för omedelbar användning.

Applikationsrapporten – Mätningar av pelarens vridmoment på formsprutningsmaskiner – ger ett perfekt första intryck av användbarheten av vår ringmätare eller StrainPad. Kontakta oss för mer information.

INDIVIDUELLT

Vi erbjuder våra kunder individuella lösningar för deras individuella utmaningar. Vi kan erbjuda våra kunder nästan vilken diameter som helst. Ta kontakt med oss så hittar vi också en lämplig lösning för din utmaning.

KRAFTFULL ANSLUTNING

Ringmätarna placeras runt respektive cylinder och dras åt med en skruv. Detta skapar statisk friktion mellan våra StrainPads och komponenten som ska mätas. Ringmätarna används främst över hela världen för maskinkalibrering och de uppnår samma noggrannhet som pålimmade töjningsgivare (DMS).

SNABB OCH ENKEL INSTALLATION

Ringmätarna placeras runt respektive cylinder och dras åt med en skruv. Detta möjliggör mycket snabb montering och demontering av ringmätarna. Detta gör också våra ringmätare idealiska för de applikationer där exakta och snabba mätningar krävs.

FUNKTIONER

- Snabb och enkel töjningsmätning på cylindrar (magnetisk eller ej)

- Mycket enkel installation (behöver endast 1 skruv)

- Noggrannhet 1 %

- Idealisk för cykliska applikationer, till exempel klämkraftsmätningar på pressar eller formsprutningsmaskiner

Ringmätare - Alternativ för töjningsgivare

- Tillverkare: Octogon Messtechnik

- Artikelnummer: Ringgauge

- Tillgänglighet: Pre-Order

Liknande Produkter

Strainpad - Alternativ för töjningsgivare

Ett helt ny sätt at mäter med trådtöjningsgivareTill skillnad från de konventionella töjningsgivarna..

Magnethållare- Alternativ för töjningsgivare

Kraft- och töjningsmätningar med bondade töjningsmätare (DMS) har länge använts inom mekanik och anl..

Lastpinnar och Pinnarlastcells för kraftmätning

LASTPINNAR FÖR KRAFTMÄTNING Lastpinnar är viktiga komponenter för kraftmätning inom ett brett spekt..

EVL Momentgivare

TEKNISKA FUNKTIONER27 vridmoment varierar från ± 0 - 0,02 Nm upp till 20 000 NmStort inspänningsområ..