Solar / PV Inspektion

NEO PV Master-produkterna erbjuder snabb och tillförlitlig inspektion och utvärdering av solcellsanläggningar, med ett helt automatiskt AI-baserat systemdiagnos. Med upp till 24 ingångskanaler (PV Master 80) och en kapacitet på upp till 1600V DC, gör den smarta IV-kurvdiagnosfunktionen det möjligt att samtidigt utvärdera flera PV-strängar och hela PV-arrayer.

Världens första och mest kraftfulla diagnossystem för solkraftverk.

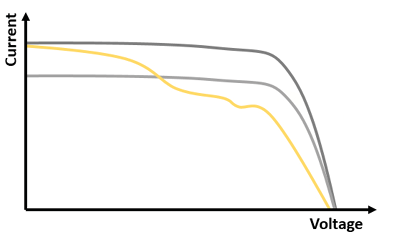

Denna teknik registrerar spännings- och strömprofilen (IV-kurva) för solpaneler från öppet kretsvoltage (Voc) till kortslutningsström (Isc) genom att applicera en belastning. Baserat på kurvans form kan olika fel upptäckas och särskiljas. Dessutom är det den enda metoden för att upptäcka mismatch-förluster.

Enkelt upptäck:

- Mismatch-förluster: Den enda metoden för att upptäcka mismatch-förluster.

- Skuggning: Upptäck skuggning och uppskatta förlorad årlig intäkt.

- Smuts/Förorening: Med hjälp av intelligenta algoritmer.

- By-pass-diodfel: Upptäck trasiga dioder (öppen eller kortslutning).

- Hotspots: Upptäck hotspots även vid låg strålningsnivå.

- PID (Potential Induced Degradation): Upptäck potentialinducerad nedbrytning.

- Cell-Sprickor/Trasigt Glas: Och andra fel.

IEC 62446-2: Fullt överensstämmande.

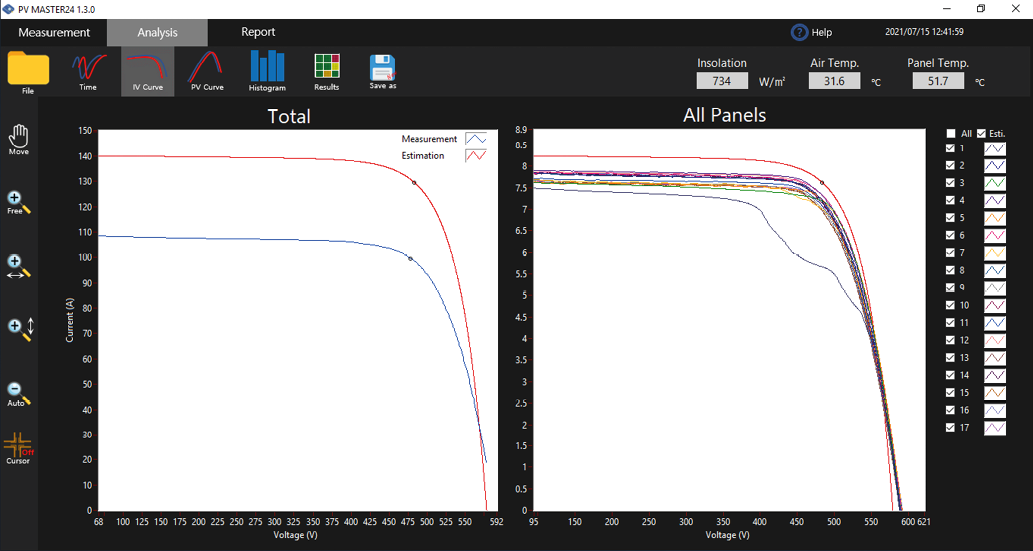

Följande bild visar ett exempel på en samtidig mätning av en PV-array med 17 strängar:

Att använda enkanals IV-mätsystem kan vara mycket tidskrävande (dagar) för inspektion av stora solcellsanläggningar (t.ex. 400 strängar för 3 MW). I kontrast kan ett flersnåls IV-kurvmätsystem inspektera solkraftverk på en mycket kortare tid (~4 timmar per MW) och ge värdefull information om mismatch-förluster.

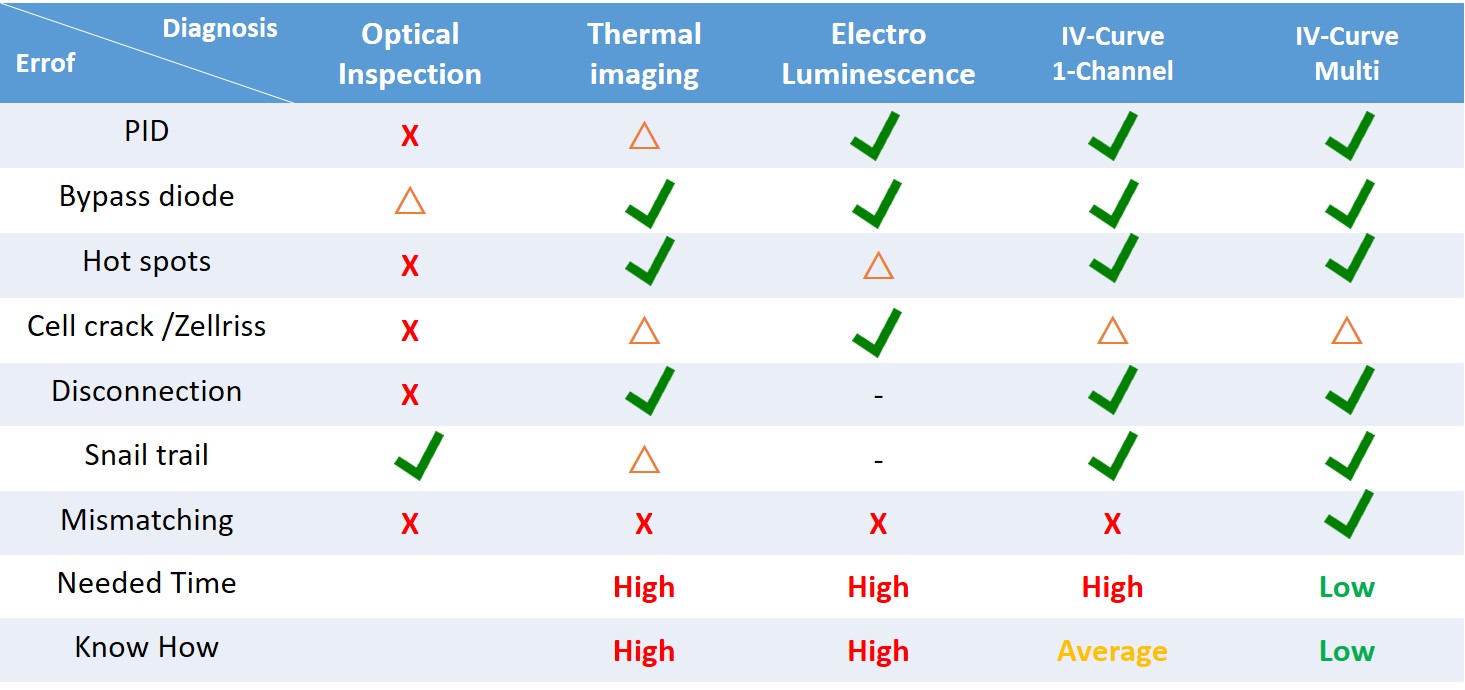

Följande tabell visar en jämförelse av olika PV/solcellsinspektionsmetoder:

PV MASTER 10

Ingångskanaler1 kanal samtidigt mätt med Time-Sync TechnologySpänningsingång1600V Potentialmätning16..

PV MASTER 70

Ingångskanaler 20 kanaler samtidigt uppmätta med Time-Sync Technology Spänningsingång 1600V Potent..

PV MASTER 80

Ingångskanaler24 kanaler samtidigt uppmätta med Time-Sync TechnologySpänningsingång1600V Potentialmä..